Tube Bender Software and Spare

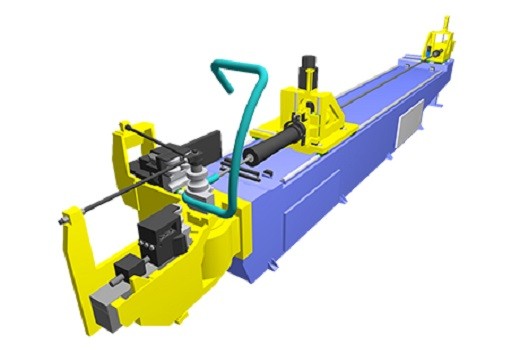

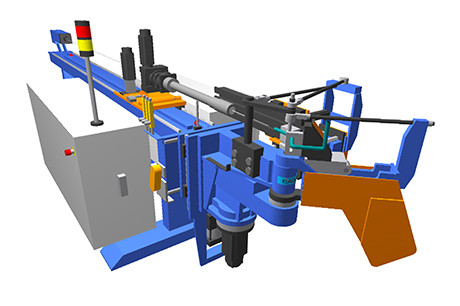

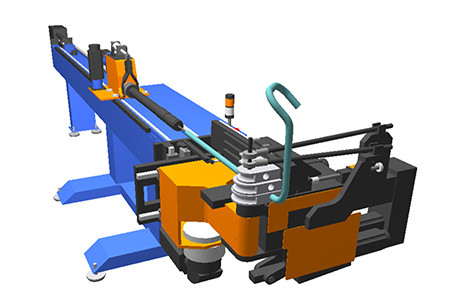

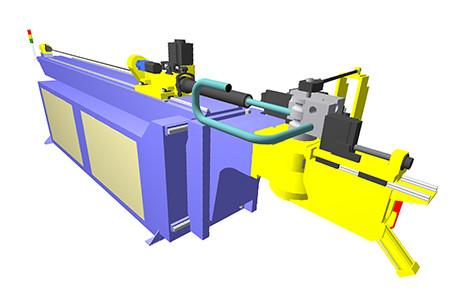

Bossray CNC tube bender and laser tube use high advantage software for easy operate and precise with 3D simulation and IGS drawings convert functions. As for easy and quick malfunction remove, the software upgrades with remote control as well.

0 products found

ViewShowcase

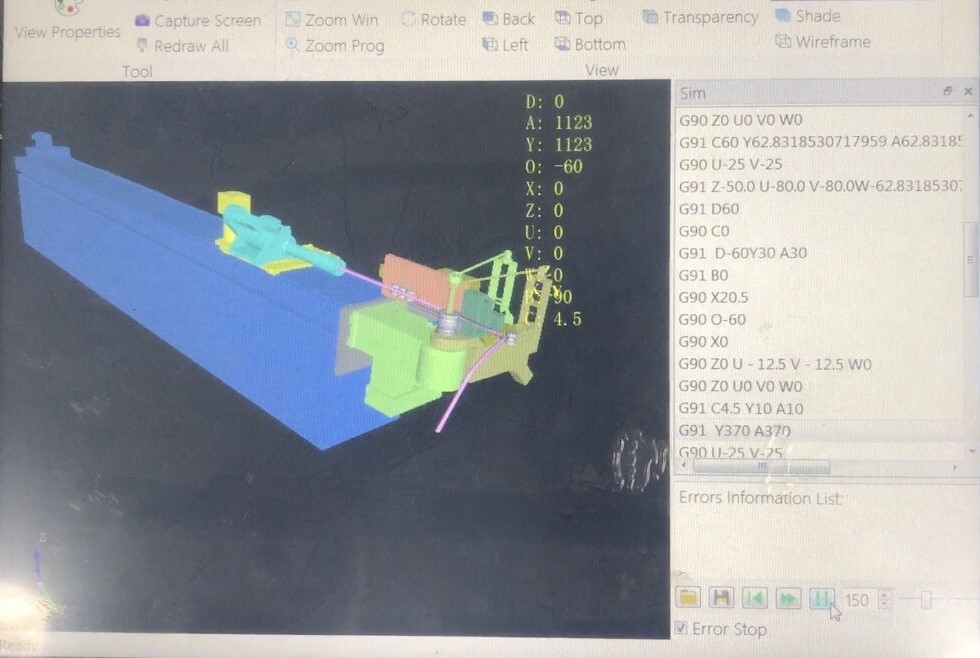

Tube bending simulation software

During discussion, we would suggest 3D IPC controller to customer.

Can I bend this tube geometry on my machine? This is the most important question that you have to ask yourself before embarking on a new tube bending job.

The answer will determine whether the tube can be manufactured as planned.

In many instances, you answer the question only after trying the part out, tying up the machine when it could be producing parts, and possibly creating waste with reject parts.

That's where tube bending simulation can make a difference.

How can bending simulation software assist me if there is interference?

Once interference with the bending sequence has been detected, the software can assist you in different ways. If two bends are too close together, the software can inform you and tell you the minimum distance the selected tool requires. You could cut the pressure die for short. If the tube collides with a nearby obstacle, the software can test alternative bending sequences, all dependent on the machine's capabilities, of course. For instance, a simple three-axis bending machine offers fewer options than a complex double-head, multil bending machine. Contact Bossray and send to us your bending drawings, we could show you on real.

Where can I use bending simulation software?

Bending simulation software can be used at several points in the fabrication process. While the most obvious position is at the bending machine itself, this is not the only option, and depending on the fabrication flow, it may not be the best one. While simulation allows you to test the tube geometry and adapt it as necessary, the design engineer needs to be notified if a tube is not bendable on the machine at all. Any changes to the tube geometry affect the adjoining part geometries, which then require testing as well. If some of these tubes have already been fabricated, this can cause significant problems, costs, and delays.

How can I use the results I get from the bending simulation?

One of the more time-consuming tasks for a machine operator is to calculate and enter the necessary data needed to bend the tube, especially if the operator has to adjust the data for overbending or revise the data if the bending sequence needs to be modified. The machine sits idle if there is no backlog of work, and if other stations in the shop are dependent on a continuous supply of bent tube, the machine becomes a fabrication bottleneck.

Which bending simulation software can I use with my machine?

The advantage of manufacturer-independent software is that it can simulate machines made by different manufacturers in the same workshop. Some applications also can run multiple tests, testing one geometry simultaneously on all machines capable of bending the selected diameter or radius. The disadvantage of third-party software is that an interface to the machine may need to be programmed. Models of the machine need to be created as well. Some independent developers cooperate with multiple machine manufacturers, however, and those manufacturers often sell the software along with the machine, Bossray giving the buyer the advantages of both options.

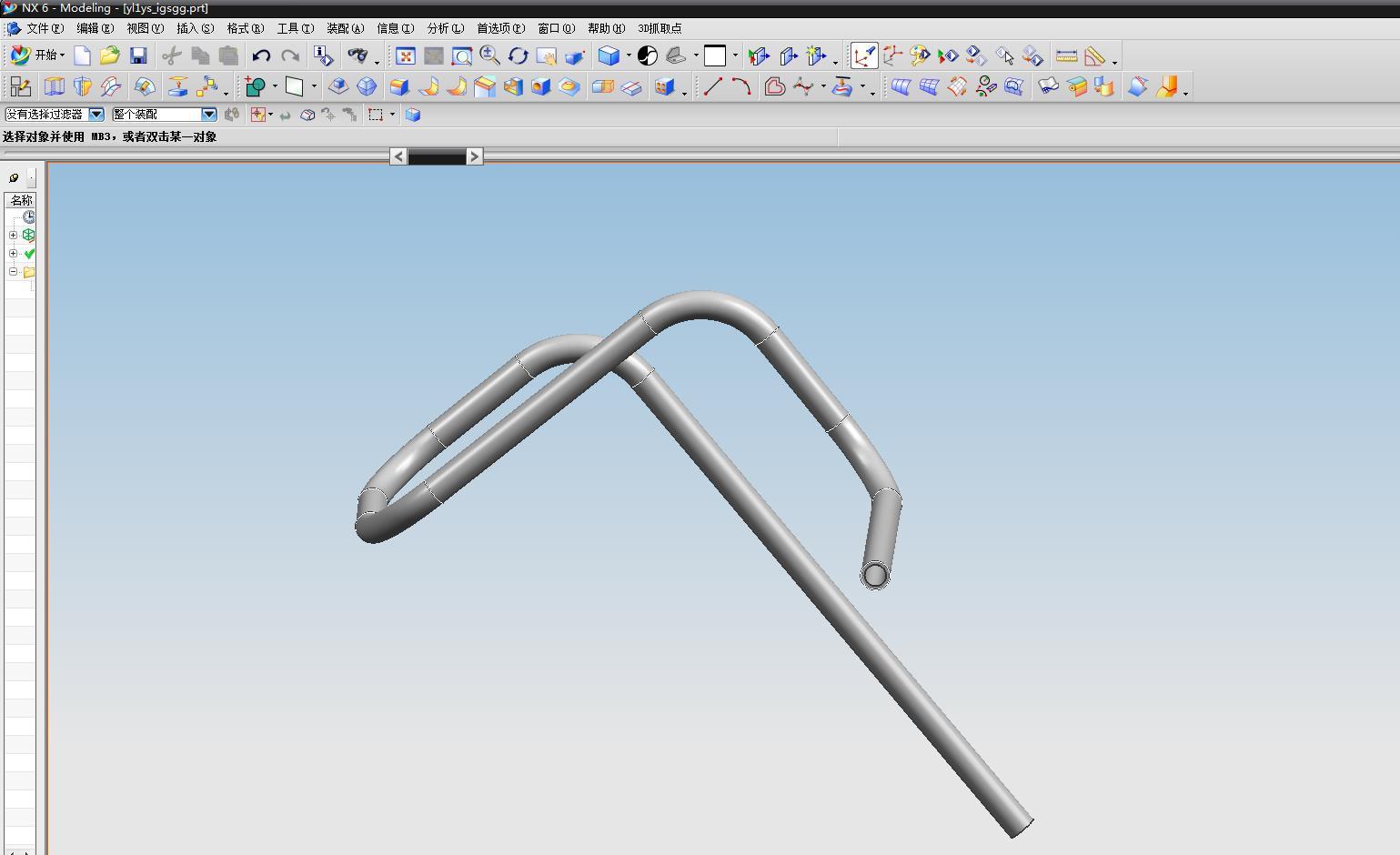

How are the models of your machines and tools created?

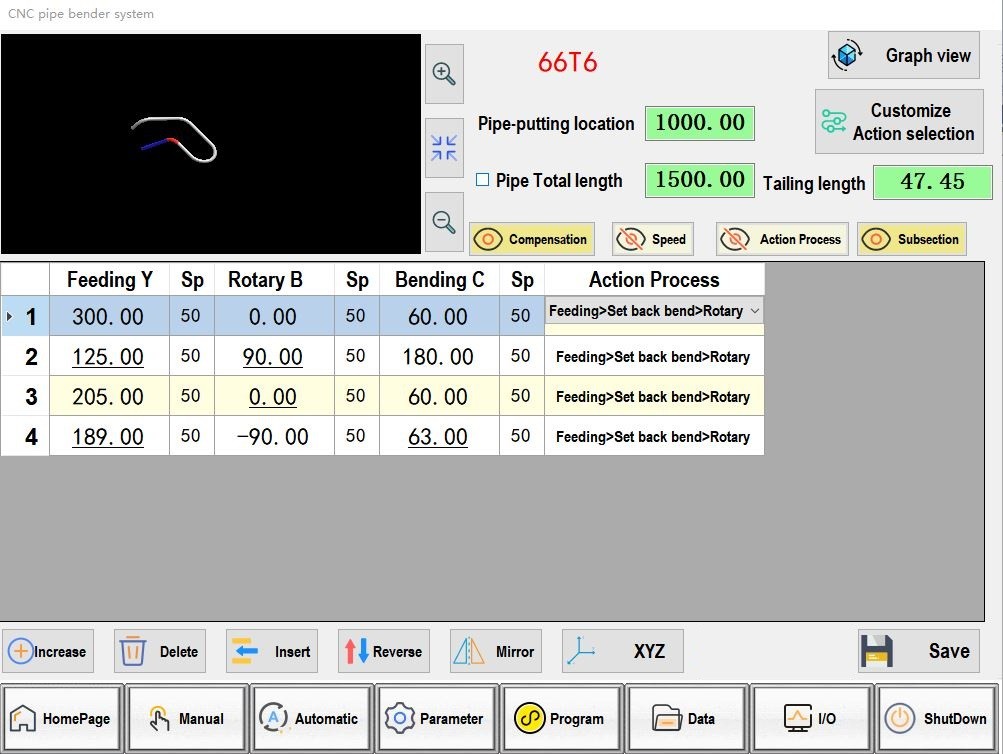

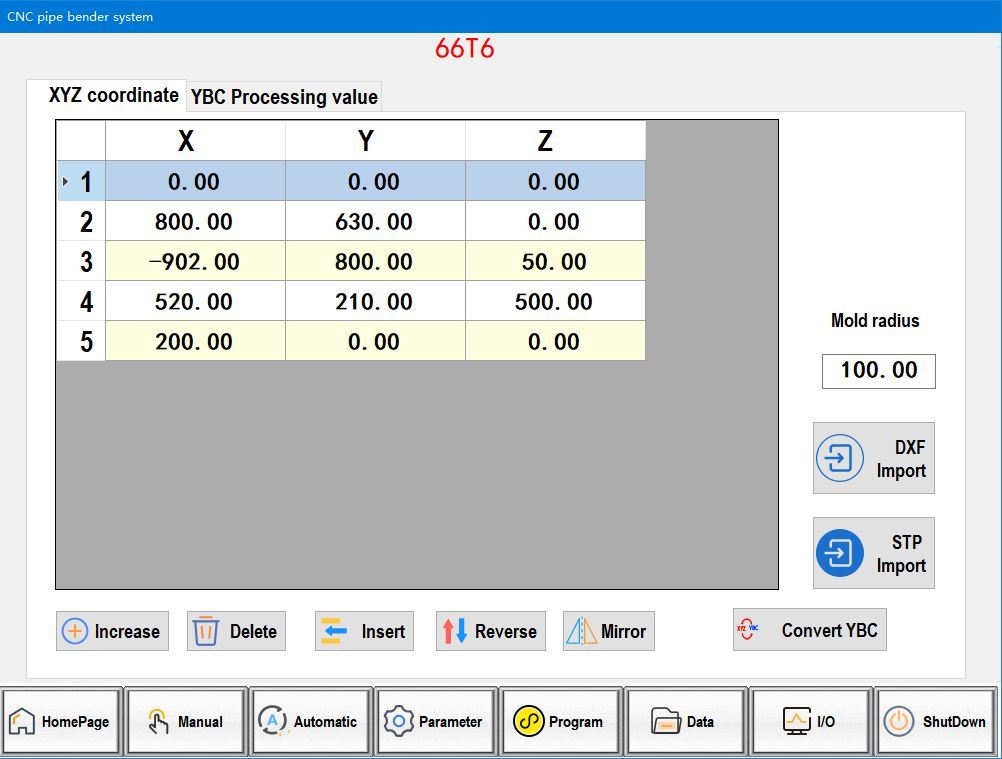

Our software is able to automatically analyse STEP or IGES files and extract the XYZ and bend data. In cases where automatic analysis isn't possible because of issues within the CAD model, the user has the option to manually select each straight or bend and then push the calculate button. The software will then automatically calculate important information from the CAD model including:

XYZ Cartesian coordinates

YBC bend data

Tube Outside Diameter

Tube Wall Thickness

Tube Cut Length

Units (Millimeters, Inches)

Can bending simulation software help me compensate for material properties?

Several material properties affect a tube bend. One of them is stretching, which thins the material in the bend. Stretching can be countered by boosting the tube during bending.

Another property, springback is the tendency of a tube to return to its original shape. This causes the tube's bent angle to differ from the intended angle. The only way to compensate for springback is overbending.

What are the limitations of bending simulation software?

While bending simulation software can be very effective in increasing productivity and reducing costs, you need to be aware of some limitations.

Most important, simulations cannot replace human expertise.

The simulation is only as accurate as the machine and the tooling models. If the models are wrong, the simulation cannot be precise. Because of this, customer always need to supervise the bending process, so you can override the results of the bending simulation if necessary.

subscription

Please send your message to us

Bossray provides you with more professional solutions and services, contact us now

- *Name

- *Tel

- *Title

- *Content