CNC Tube Benders

Bossray CNC Tube Benders handle everyday bending tasks as well as the most demanding, high-precision jobs. These CNC tube benders are perfectly suited for production in any industrial setting including Automobile, Motorcycle & ATV, Fitness GYM, Medical and Furniture, etc.

- Introduction

- Bending Principles

- Features

- Parameters

- Related Products

- Components

- Software

What is CNC Tube Benders

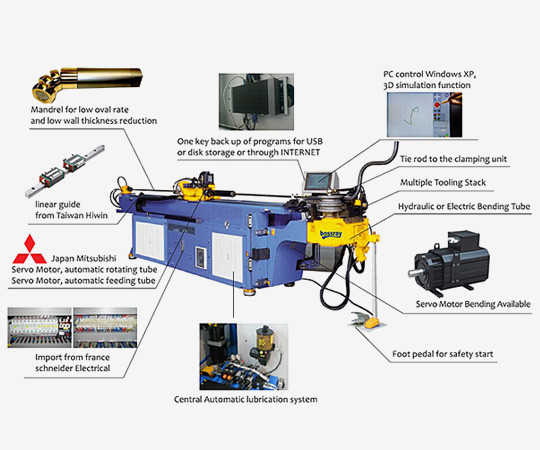

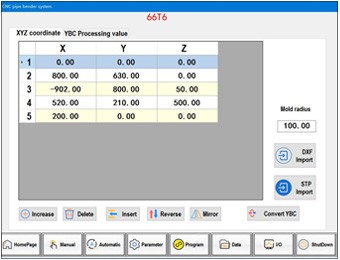

The CNC Tube Bender is composed of three parts: mechanical part, hydraulic system, microcontroller, PLC or PC control system. The mechanical part mainly consists of a rotating pipe clamping device, a bending pipe transmission device, a booster device, a machine bed and a bending tooling fixing device, etc. The CNC pipe bending machine is located in a three coordinate point control system, and the bending and forming of the pipe is achieved by controlling the motion of the three coordinate axes through the pipe bending motion command (NC command). The digital code information includes the YBC data program or vector coordinate point program, the bending speed of the machine, the clamping force and rebound amount of the clamping block and auxiliary push, etc.

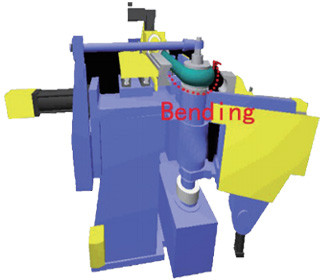

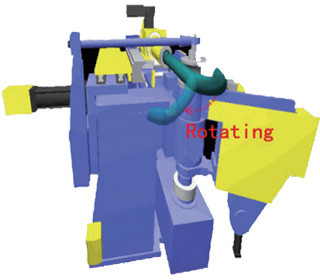

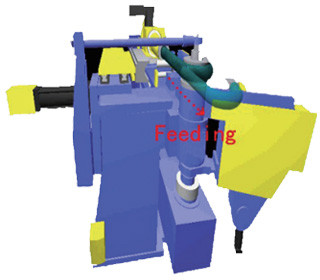

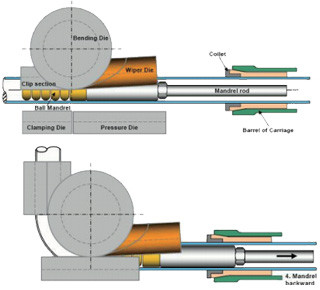

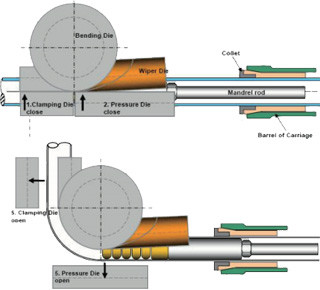

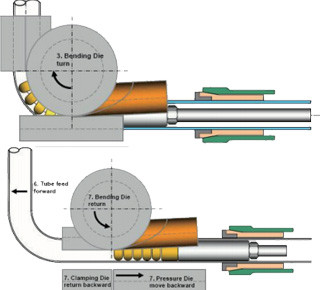

Bossray CNC Tube Bender Bending Principles

CNC Tube Bender Features and Advantages

✔ Bend-arm (C-axis) by servomotor.✔ Clamp die by hydraulic; pressure die by hydraulic.✔ Carriage (Y-axis) by servomotor.✔ With rear booster is driven by a servo motor.✔ Collets (B-axis): rotation by servo motor, grip by hydraulic.✔ With the roll bending function (ROLL BENDING), can make a big radius by rolling.

✔ Tooling shift: motion up-down by hydraulic or servomotor with brake; left-right by servomotor.✔ PDA (pressure die assist): by hydraulic or servomotor.✔ Automatic moving parts lubrication systems.✔ Standing pedestal, serves emergency stop, double-hand startup, and remote control.✔ Industrial PC (windows system) assorted with touch screen display, 3D preview, remote control, 3D bending simulation, and collision prevention.

Tube Bender CNC Series Parameters

|

Type

|

Bending capacity(mm)

|

Drive

|

|

SB-25CNC

|

25.4x1.0

|

AC servo

|

SB-38CNC | 38.1x2 | Hydraulic or AC servo |

SB-50CNC | 50.8x2 | Hydraulic or AC servo |

SB-63CNC | 63.5x2 | Hydraulic or AC servo |

SB-75CNC | 76.2x4 | Hydraulic or AC servo |

SB-89CNC | 90x4 | Hydraulic or AC servo |

SB-100CNC | 100x6 | Hydraulic or AC servo |

SB-115CNC | 115x10 | Hydraulic or AC servo |

SB-130CNC | 130x10 | Hydraulic or AC servo |

|

SB-159CNC

|

159x10

|

Hydraulic or AC servo

|

|

SB-168CNC

|

168x10

|

Hydraulic or AC servo

|

Tube Bender CNC Series Related Products

12 products found

ViewShowcase

Intelligence CNC Tube Benders adopts IPC system and professional software, 2 inches capability.

It can bend Max. tube OD=63.5mm. Ball Mandrel draw bending. Low deformation rates.

CNC Mandrel Tube Benders adopts IPC system and professional software of Benders, 76mm OD.

CNC automatic rotation, feeding, and bending machines, 38mm max bending capacity.

Bossray CNC Pipe Benders is the advanced Benders with multi-axis servo motor controlling.

Applys professional skills of industrial IPC and CNC Benders into multi-axis servo driving.

SB-100CNC with high precision and complex 3D cold bending for Automobile and Motorcycle parts.

It can bend Max. tube OD= 4 1/2 inches, Roundness and flattening are good.

It can bend Max. tube OD 130mm. The moves are controlled by the advanced IPC system.

3D cold bending of each thick wall or thin wall steel and alloy tubes. Automatic CNC bending.

It can bend Max. tube OD 168mm, Heavy duty CNC ball mandrel bending.

Intelligence CNC roate head pipe bending machines, 50mm max bending diameter.

Tube Bender CNC Series Main Components List

Our parts suppliers come from well-known brands around the world

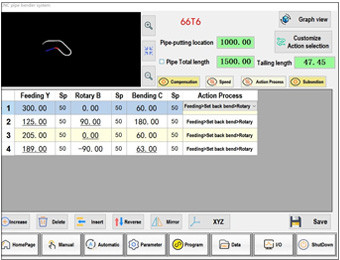

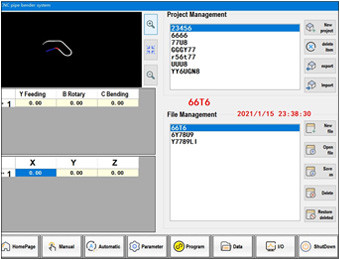

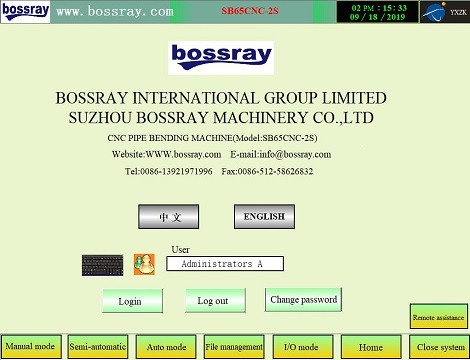

Tube Bender CNC Series Software

IPC controller

This is international general mechanical control system, which combines the operation of industrial control computers, as well as the high openness of PLC programming, and the stability of action control. This architecture can further improve the performance of the pipe bending machine, enhance the coherence of actions, and improve the response efficiency of the equipment.

It can easily achieve multi axis linkage, simulation and display functions.

It can easily achieve multi axis linkage, simulation and display functions.

PLC controller

This control system is a mainstream system with PLC as the core and touch screen as the display carrier. The system has high openness and powerful functions, and is suitable for equipment such as fully automatic pipe bending machines, CNC pipe cutting machines, automated pipe bending machines, and pneumatic pipe bending machines. In addition, the vast majority of automation equipment in the current market adopts this system, which is also very suitable for online use with robots.

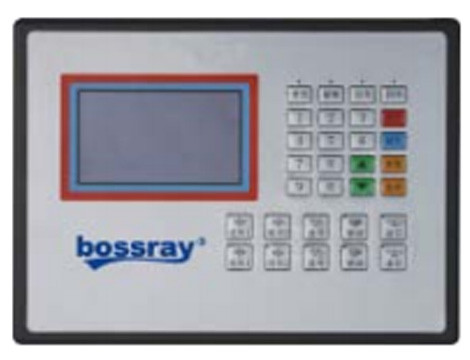

Microcontroller

The microcontroller system, where the actions of the hydraulic pipe bending machine are integrated on a circuit board chip, and the system is completely locked, which is only usable and cannot be modified. But the benefits are obvious, with simple principles, fewer components, stable price, and suitable for use in the vast majority of single end pipe bending machines. In addition, microcontrollers have also been widely used in equipment such as tube end forming machines, circular machines, and pipe cutting machines.

We're Here for You Anytime, Anywhere

We are at your service anytime, anywhere

Bossray provides professional services throughout the pre-sales, sales and after-sales processes to solve various problems for you.

subscription

Please send your message to us

Bossray provides you with more professional solutions and services, contact us now

- *Name

- *Tel

- *Title

- *Content