Home / All / CNC Tube Benders /

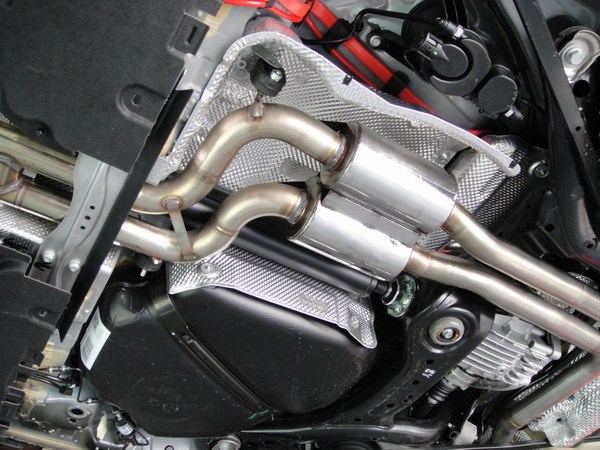

CNC Tube Bending Machines For Stainless Steel Exhausts System 3 1/2 inches Capability

CNC Tube Bending Machines For Stainless Steel Exhausts System 3 1/2 inches Capability

Detail Information

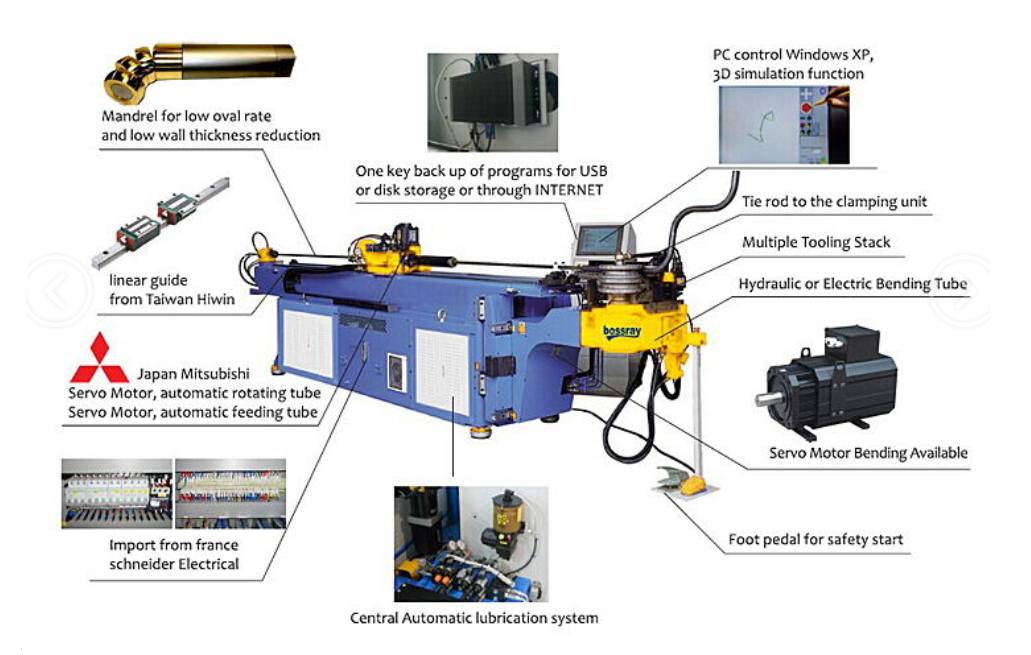

89CNC Tube Bending Machines 3 1/2 inches

Bossray CNC Mandrel Tube Bending Machines handle everyday bending tasks as well as the most demanding, high-precision jobs. These CNC Mandrel Tube Bending Machines are perfectly suited for production in any industrial setting including Automotive, Motorcycle & ATV, Fitness GYM, Medical and Furniture, etc. Our newest CNC Mandrel Benders are available in all-electric, hybrid electric, or hydraulic drive models.

Bossray CNC Mandrel Tube Bending Machines provide energy-efficient production with the most advanced technology and features. Additionally, our CNC Benders function alone or seamlessly integrate into any production setup. Bossray can combine any CNC Benders with our automated loaders/unloaders robot arms or CNC laser tube to create a custom work cell solution. These custom work cells increase production and free up your staff for more important tasks. Request a quote for any of our CNC Mandrel Tube Bending Machines online.

89CNC Tube Bending Machines Parameter

|

Model |

SB-89CNC |

|||

|

Bending capability OD×WT (carbon steel):

|

Φ88.9×4.0 mm |

|||

|

Bending radius: |

320mm |

|||

|

Bending angle |

0~180° |

|||

Max bending length with mandrel: | 3500mm | |||

Bending speed: | Max. 100°/sec | |||

Bending accuracy: | ±0.1° | |||

Feeding speed: | 1000 mm/sec | |||

Feeding accuracy: | ±0.1 mm | |||

Rotating speed: | 180°/sec | |||

Rotating accuracy: | ±0.1° | |||

Tools stack: | 1 or multiple | |||

Bending: | Electric Servomotor or Hydraulic | |||

Feeding/Booster: | Electric Servomotor | |||

Rotating: | Electric Servomotor | |||

Work head shift (horizontal): | Electric Servomotor option | |||

Work head shift (vertical): | Hydraulic /Electric Servomotor option | |||

System hydraulic pressure: | 14 MPa | |||

Packing size refer: | 5200×1150×1450mm | |||

Weight refer: | 4000kgs | |||

Video

89CNC Tube Bending Machines Video

It is the first choice for the field of aerospace,nuclear power, automobile, motorcycle, shipbuilding, petrochemical,electricity, gas, boilers, fitness and sports equipment to bending pipes. 1-9 stacks tooling is optional.

89CNC Tube Bending Machines Features and Advantages

- 1Bend-arm (C-axis) by Hydraulic / Servomotor

- 2Clamp die by hydraulic or servomotor; pressure die by hydraulic or servomotor.

- 3Carriage (Y-axis) by servomotor.

- 4With rear booster is driven by a servo motor.

- 5Collets (B-axis): rotation by servo motor, grip by hydraulic or servomotor.

- 6 With the roll bending function, can make a big radius by rolling.

- 7Tooling shift: motion up-down by hydraulic or servomotor with brake; left-right by servomotor.

- 8PDA (pressure die assist): by hydraulic or servomotor.

- 9Automatic moving parts lubrication systems.

- 10Standing pedestal, serves emergency stop, double-hand startup, and remote control.

- 11Industrial PC (windows system) assorted with touch screen display, 3D preview, remote control, 3D bending simulation, and collision prevention.

OPTION

- 1Multi radius

- 2Left and right direction bending

- 3Punching device

- 4Cutting device

- 5Safety fence

- 6Safety mat or Light curtain protection

- 7Bend 1.0*D radius or more tight radius

- 8Fan / Water / Oil cooling system

- 9Robot loading and unloading systems

- 10Safe blanket / Infrared alarm device

- 11SIEMENS 3D convert

- 12Electric power supply transformer

- 13Quick tooling change

- 14Special tooling design and brass mandrel

Related Products

Review

- Loading...

Please send your message to us

Bossray provides you with more professional solutions and services, contact us now

- *Name

- *Tel

- *Title

- *Content

subscription

Please send your message to us

Bossray provides you with more professional solutions and services, contact us now

- *Name

- *Tel

- *Title

- *Content