Leading CNC Tube Benders Manufacturer

Our CNC tube benders can improve manufacturing speed and increase your bottom line, High cost performance.

The frames, exhaust system, components, and accessories are elements in which the machining of a tubular parts, whether laser cutting, bending, often comes into play. A single professional supplier, expert in these processes and able to integrate the systems in a single production process is a guarantee of quality, efficiency, and profitability.

Unleash your imagination and generate new ideas with BOSSRAY engineer. Create new design solutions and try them out now with the integration of tube bending and laser cutting that guarantees you the right part from the start. Reap the benefits of a single source supplier for your production process.

Many production steps of agricultural and industrial vehicles involve working on tubes. BOSSRAY, with its complete range of systems, can offer a solution to every need.

The availability of a unique partner able to provide systems for every tube processing job, from laser cutting and end-forming to bending, and to have the ability to have a completely integrated process offers several advantages.

Laser cutting of tubes, bending of tubes and wires, end-forming, different technologies for different parts of the vehicle, such as chassis, seats, exhaust systems, and air and fluid lines etc.

Efficiently address the needs of a variety of different industries, slash production costs, and respond to customers with quality in the required time. To meet these needs, you need a complete range of machines with flexible and reliable systems that cover every possible demand. BOSSRAY is a one-stop supplier able to provide an answer to every problem.

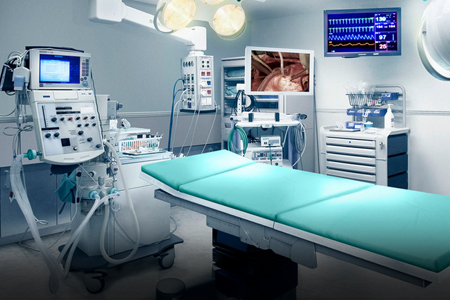

Maximum precision and optical perfection are the greatest challenges in the manufacture of medical equipment. Moreover, the size of the tubes to be bent and the batch sizes vary widely. In addition, the materials used for medical equipment are especially diverse. In the case of wheelchairs and wheeled walking aids, it is important to reduce weight. It's a good thing that our cold bending technology does not attack the structure of the materials. BOSSRAY tube bending machines satisfy the most exacting requirements in terms of processing quality, sustainability and efficiency.

Our tube bending machines enable our customers to process even high-strength materials – from very large to extremely thick-walled and thin-walled tubes with the smallest bending radii. They produce complex geometries in a single operation and manufacture three-dimensional tube systems without the need for welding.

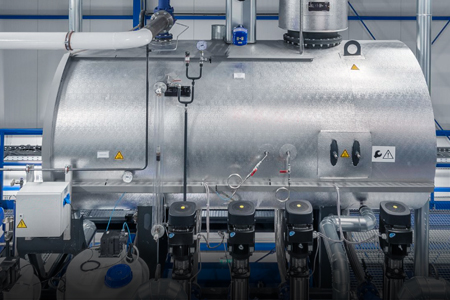

The efficiency of a combustion chamber depends on being able to bend the tubes to extremely tight radii in order to provide the largest possible surface area for heat transfer. The high-strength materials used represent an enormous challenge. We have developed bending machines that ensure consistent precision especially for the boiler and power plant industry. They are extremely stable and suitable for use in tough conditions.

BOSSRAY systems are the solution to the needs of the household appliances sector.

With 2D and 3D laser cutting systems, make any kind of geometry, innovative and refined design shapes with smooth and defined cutting edges on materials, including aluminium or stainless steel. Plus our CNC tube bending systems for meet your shapes request.

Each system can be easily integrated into work cells with various levels of automation for rapid, yet flexible, production to meet growing needs.

New technologies for the buildings construction of the future. BOSSRAY systems for processing tubes and beams offer the opportunity to reduce the overall costs of building a structure. Innovative solutions that exploit the potential of laser systems without which certain processes would be impossible or unprofitable.

The world of air treatment requires productivity, automation, precision, and repeatability. That is why it makes sense to rely on a single, experienced supplier with both single systems and flexible manufacturing cells. Our smart solutions satisfy the exacting requirements in terms of bend quality, especially when it comes to reducing the wall thicknesses and ovality of the tubes.

Bossray has been committed to providing solutions for Tube bending and cutting machines since its establishment in 2003, providing over 3000 machines and solutions in 33 countries, providing excellent machines for tube bending and cutting request.

Learn More

From accessories to metal fabrications as well as assemble, we have a strict quality control system to meet customers' quality requirements, satisfy them, and achieve value for money, we would have full test done before ship the machine to final user.

Learn More

As a leading manufacturer of CNC tube bending and laser cutting machines, Bossray can customize machines according to customers' special request in needs.

Learn More

We have local and international service partners to offer the machine install and training services, with fast machine parts deliver support, maintiance and tooling support etc.

Learn More

Bossray Machinery is the State-of-the-art manufacturer of CNC Tube benders and Laser cutting machines. As be your specialist technology partner for high-performance bending and cutting machine solutions that are perfectly tailored to your individual needs. For decades, our company has been synonymous with innovation and quality, thanks to our ongoing efforts to improve set new standards in tube bending and laser cutting technology. Applying our passion, inventiveness and decades of experience, we develop unique and innovative products to ensure your lasting market success.

Passed European CE and Chinese official design and invention patent certification.

Providing different CNC Tube bender and Laser cutting solutions for more than 20 years, Bossray is leading to the extraordinary technology and experience in tube bending and laser cutting field. We have more than 20 patents for the CNC tube benders and Laser cutting machines. We design and produce new model machines for more than 10 types every year. We are supplying tailored machines and all kinds of tube bending and cutting solutions for the customers world widely.

We say NO to quality defect.

The machine core parts are processed in door. Electric and hydraulic components are international famous brands. Choosing very good suppliers to help us build stable and premium quality. Strict QC department keeps the defective parts away from our machines. Never use fake parts. Updating of staff knowledge through courses and training activities.

Bossray has the R&D team, production team, technical support team and sales service team. All teams are hardworking and responsible for the customers. We a mutually matched, mutually cooperative, mutually supportive, united team.